Our friction pendulum verification procedure is unique.

The experience gained over the years has allowed us to develop the most complete and exhaustive process on the market, which is why we are the only ENAC-ILAC accredited laboratory in Spain for verifying the properties of the friction pendulum. For more information on the added value of the ENAC-ILAC accreditation and its international validity visit our page Acreditation.

It is made up of the highest demands of national and international standards, so it will always meet your expectations and requirements:

- UNE 41901 / UNE 41902

- CEN/TS 16165

- BS 7976-1

- BS 7976-2

- BS 7976-3

- UNE EN 13036-4

- UNE-EN 1097-8

- EN 16165

The final report details all the inspections, observations, required actions, equipment adjustments and final results, offering a single view of the equipment status.

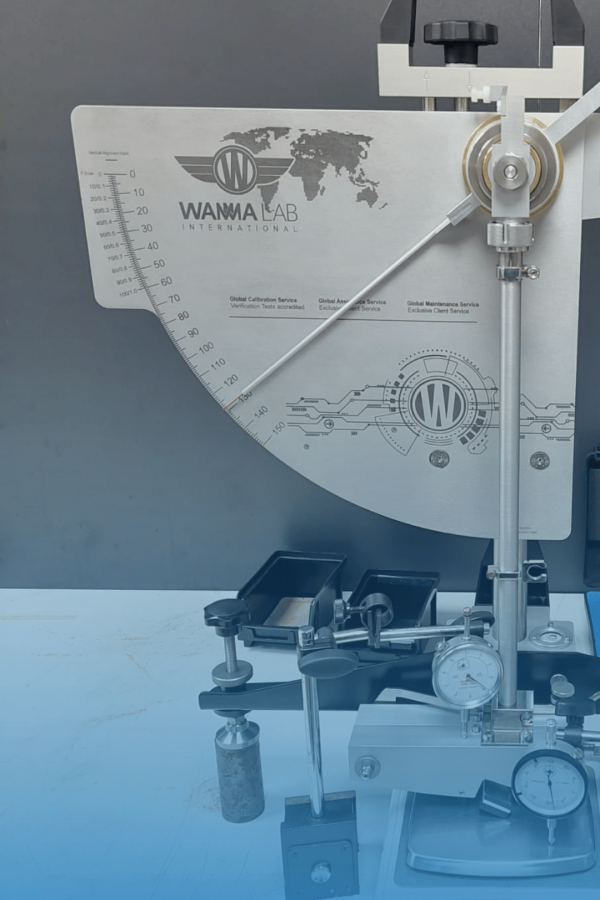

THE PROCEDURE CONSISTS OF

- Pre-calibration verification

- Detailed inspection

- Checking the dimensions of the pendulum scale

- Checking the swing arm center of gravity and shoe mounting

- Checking the effective spring tension

- Checking the force / displacement characteristics of the shoe

- Checking the leveling of the equipment

In addition to all these checks, the customer is advised on equipment care and maintenance, so that his pendulum is always like new. We manage and carry out repairs of faulty or damaged pendulums.